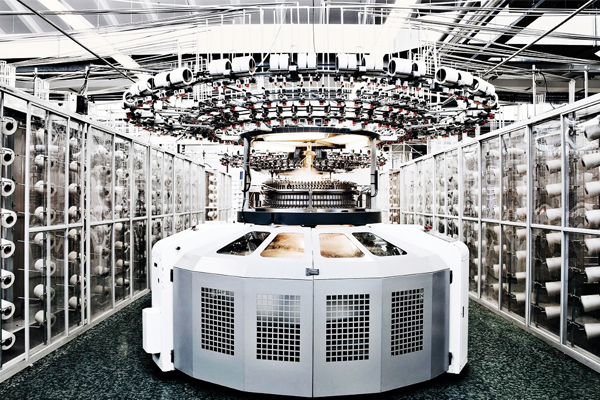

Knitting

Our knitting requirements are fulfilled by our partner who supplies us the single jersey and PIQUE honey comb fabric on all dia machine with 20, 24 and 28 gauge.

For Examples: 24" 26" 30" 36"

Printing

Along with our processing division, our printing division has the capacity of producing 21 tonnes/day in both woven and knitted fabrics. Machineries include state-of-art stormac and zimmer rotary printing machines in the facility.

Cutting

Cutting is the main phase in garment making. A Garment can't be made without cutting. In our firm cutting is done by the persons who are perfectly skilled and keeping in mind the FASHION FITS. We have modern hand cutter and pattern cutting machines.

Stitching

Some of the most sophisticated machines that have become de facto standards in the textile industry are used by SAF Exports. Our factory is situated in center of the Tirupur City. We have around 150 sewing machines with a work area of 30,000 Sq Ft. With this installed capacity we saw about 1,00,000 garments per month.

Checking

Inspection/Finishing Unit independent of production to ensure the Quality and Specifications of Buyers are met.

Ironing & Packing

Stream We depend on modern methods for ironing. We use adjustable flat horizontal tables and modern steam pressing boxes for ironing garments. Vaccum sucking machines are used to take away the excess moisture in the garment due to Steam Ironing.We buy our Packing Materials from leading suppliers and professional providers to Garment Exporters. We use only poly propylene and polyethylene bags with colour printing. For all kinds of Hangtags, Sticker and patches we depend on the best which meets the global standards. We use only corrugated Carton boxes for packing.

OUR COMPANY FACTS

Profoundly rooted since 2004, SAF Exports gets on its persistent upgrade of technology and methodology for the furtherance and consistency. The reputation as one among the prominent manufacturers and exporter in the garments segment keeps the success story inspiring capturing multiple milestones. In the present day the company shows up with around 150 - 200 skilled employees each working on high accent of perfection

Skilled Employees

Sq.Ft of operational area

Pieces prodcution / month